DATE: 2025/10/30

SEER Robotics Returns to CeMAT, Presenting a Feast of “Embodied AI+Industry” Integration

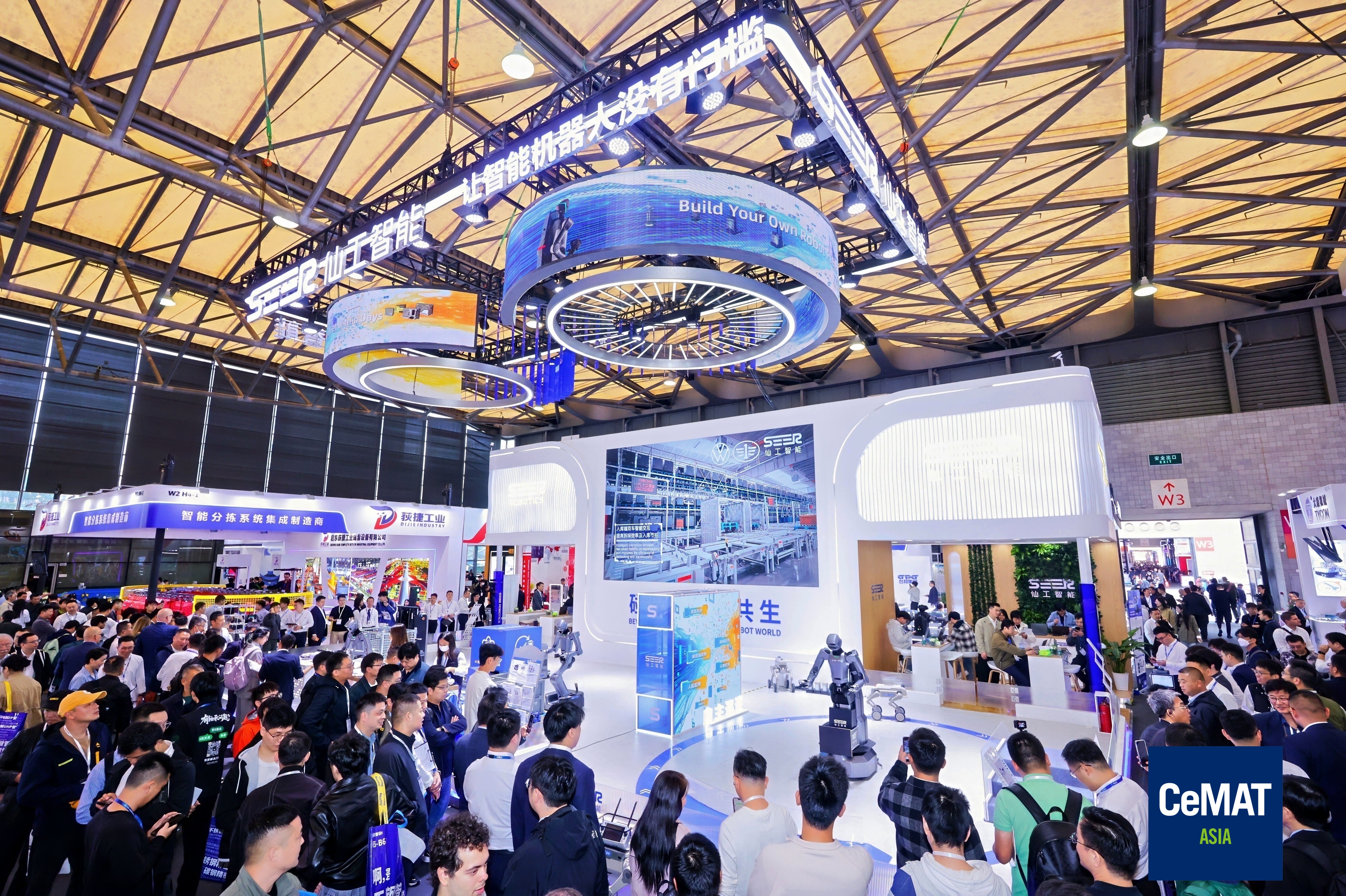

On October 28, the CeMAT ASIA 2025 officially opened at the Shanghai New International Expo Center.

SEER Robotics made a grand return with the theme "Collision • Boundary-breaking • Symbiosis," presenting a variety of new embodied intelligence products, the upgraded Nebula platform, the newly launched smart robots, and robot control systems at booth G4 in hall W2. This showcased SEER Robotics' strong capabilities and innovative achievements as the first large-scale open platform for intelligent robots.

Let the imagination of embodiment land and the logistics experience be disrupted!

Embodied Power! Joint Display of New Products in Multiple Scenarios

Based on our continuous in-depth exploration of industrial scenarios and forward-looking insights into the trend of embodied intelligence, SEER Robotics, in collaboration with our ecosystem partners, launched the new embodied intelligent humanoid robots and quadruped robot dogs equipped with the SEER Robotics robot brain—the control system. Five new embodied products made their first collective appearance, vividly demonstrating the successful implementation of embodied intelligence in industrial scenarios and deeply empowering real business needs.

1. Industrial-grade flexibility, humanoid real-scene operation

In the exhibition area, five humanoid robot systems demonstrated the comprehensive solutions from single-machine performance to overall solutions, covering typical industrial links such as material handling, transportation, and inspection. They showcased the comprehensive breakthroughs of humanoid robots in terms of high degrees of freedom, high flexibility, and intelligent interaction.

The X1-PRO, an upgrade from the first-generation product, features a bending structure design that supports 45° bending operations. It is equipped with a wheeled omnidirectional chassis and a buffer platform for material handling and transportation.

The whole machine has a lifting height of 700mm, offering greater flexibility for low-level operations and flexible pick-and-place in complex environments. The total degrees of freedom reach 40, utilizing a bionic structure with a 7-DOF single arm design. The single arm has a standard load capacity of 6kg, with a maximum short-term load of 16kg for both arms.

It integrates advanced intelligent large model technology, enabling strong generalization capabilities and natural language task interaction. Only a small amount of data and short training time are required in a single scenario to achieve high task success rates.

The X2-PRO is a wheeled humanoid robot system jointly developed by SEER Robotics and our partner, Astribot, for practical industrial applications. The robot has 25 degrees of freedom, with the upper body using Astribot's newly released rope-driven upper body, Astribot S1-U, and the lower body using SEER Robotics' latest omnidirectional mobile platform.

This robot adopts a modular design concept, decoupling the rope-driven upper limbs and the mobile chassis for flexible configuration, easy mass customization, and maintenance. It provides a new paradigm for the design and engineering implementation of wheeled humanoid robots. This architecture not only simplifies the R&D iteration costs but also enables the robot to quickly adapt to various industrial scenarios such as warehousing, manufacturing, logistics sorting, material handling, and collaborative transportation, achieving truly replicable deployment.

In the dynamic area, another humanoid robot equipped with the SEER Robotics control system, jointly launched with Astribot, smoothly demonstrated material box handling and transportation tasks and interacted fluently with the audience. This showcased the core strength of the SEER Robotics control system and the capabilities of the Astribot rope-driven body in dexterous operation and safe force control, forming a closed-loop intelligent system integrating "operation + mobility."

Based on the cooperation between the two parties, more complex mobile operation capabilities will continue to be unlocked in the future, such as dynamic obstacle avoidance, flexible docking, and human-robot collaboration. This will provide a solid foundation for multi-task execution in industrial scenarios.

2. Extreme flexibility, the robot dog team makes an appearance

The robot dog "team," with its excellent dynamic balance and terrain adaptability, became another focus. It easily copes with complex environments such as slopes, steps, and rugged roads. Its core capability lies in the SEER Robotics control system, which integrates 3D autonomous navigation and AI reinforcement learning control algorithms, endowing the robot dogs with intelligent decision-making and autonomous action capabilities.

The D1-W series is a new navigation-oriented wheeled-legged robot dog, with optional point-foot and wheeled-leg structures. It features a high-strength body frame, an IP54 protection rating, corrosion-resistant joints, and supports operation in a wide temperature range of 0-40°C. It is suitable for a variety of indoor and outdoor scenarios.

The D2-W series is a new patrol-oriented wheeled-legged robot dog, also supporting point-foot and wheeled-leg options. Its unique advantage is the integration of multiple upper modules such as thermal imaging, sound pick-up, and strobe lights, establishing a three-dimensional patrol capability. It achieves 24/7, all-round abnormal monitoring and instant audio-visual-light voice early warning, forming an intelligent patrol closed loop of "detection-early warning."

Looking for robots? Visit the Nebula Platform

There are no two identical factories in the world, which means that industrial scenarios vary greatly. The Nebula platform supports customization in terms of functionality, structure, and appearance to accurately match different business scenarios.

It has now been officially upgraded to version 2.0, creating a robot platform from robots, intelligent simulation, and the surrounding mall in all aspects to accurately match different business scenarios. It is committed to upgrading the high-threshold mode of obtaining robots from "project customization" to the standardized experience of "product selection", building your own robot fleet within days!

A wide range of robots: covering various models, quickly select the robot you want.

Visual configuration: quickly configure through functional equipment, optional parameters, and appearance customization. The 3D effect is rendered in real-time; what you see is what you get, clear and intuitive.

Intelligent simulation: quickly scan the environment, high-fidelity 3D Gaussian reconstruction, accurate simulation, three steps to run the factory in the digital world first, and make business decisions one step ahead.

Surrounding mall: a rich variety of robot peripherals meet diverse needs, from planning to long-term operation, fully safeguarding the stable and efficient operation of each robot, continuous evolution, and worry-free.

The exhibition site brings four new industrial intelligent robots on the Nebula platform, fully demonstrating SEER Robotics' multi-scenario exploration results and solution innovation capabilities in the industrial field:

The intelligent delivery robot P300 breaks through the traditional computer end limit, and realizes mapping, editing, task configuration, and other operations through the body screen "one screen integration"; it supports pathless navigation and stationless navigation algorithms, can automatically optimize routes, and flexibly cope with complex scenarios.

The E-type handling robot SPR-DTE10-JB has excellent pallet compatibility, fully compatible with nine-angle, cross, square, closed, and other pallet types, easily coping with diversified handling needs, and showing excellent scene adaptability.

The omnidirectional intelligent forklift SFL-CDD10-OS has 360° omnidirectional movement capability, suitable for dense area operations, high-precision perception, and built-in AI algorithms, supports adaptive identification and forking, accurately completes multi-layer goods stacking and disassembly, and controls errors to the millimeter level.

The single-fork intelligent forklift SFL-300L breaks through space limitations with its extremely compact design. The body width is 400mm, only 1/3 of the ordinary forklift, and the turning radius is as low as 600mm. It has no pressure in straight driving and turning in narrow passages. Since its launch, it has become the preferred solution for lightweight and high-flexibility handling scenarios.

Control System: Building the Technological Foundation

1. Super brain, AGI empowered controller family

The SEER Robotics SRC series core controller, as the "super brain" of the robot, is based on a 100% self-developed architecture to ensure the independent control of core technology and extreme performance. It continuously empowers the intelligent upgrading and scene implementation of various robots.

The latest embodiment intelligent controller SRC-5000 has a comprehensive upgrade in computing power and deeply integrates AGI technology. It significantly enhances the robot's perception and understanding capabilities in complex environments. With high stability, high real-time performance, and high performance, it provides technical support for the large-scale implementation of humanoid robots.

By the end of 2024, the SRC controller had adapted to more than 300 types of components. Customers can build their own robots in a modular way, like "building blocks", making robot development barrier-free.

2. M4 AI version released, defining a new paradigm for robot management

An efficient, reliable, and flexible robot solution cannot be separated from strong software support. The M4 intelligent logistics management system has been officially upgraded to M4 AI and released three AI-empowered products, reshaping the interaction and control methods between robots and intelligent logistics systems:

M4 AI assistant (Agent): A new way to manage and control robots, smarter and easier to use, truly suitable for daily project use scenarios;

M4 Industrial Robot Large Model Base: Solves the problem of large model implementation in the fields of robots and logistics, and provides special training and adaptation for large models in the industrial field;

M4 Robot Management and Control MCP Service: Supports Deepseek, OpenAI large model calls to M4 functions, and then controls business systems, scheduling systems, and robots.

As the first product of SEER Robotics to integrate large models into standard products and implement functions, M4 AI is also the first product in the industry to combine large models with mobile robots and the core business of industrial logistics. It is committed to disrupting the traditional robot application pattern.

At the same time, the M4 intelligent robot scheduling system QuickFleet continues to iterate and has formed core advantages such as strong business understanding, leading algorithms, high scalability, and easy-to-use. It realizes efficient collaboration and lightweight deployment under multi-model and complex scenarios.

Strong business understanding: Based on the overall architecture of M4, it adapts to more long-tail needs, takes into account both warehousing and distribution scenarios, and has strong adaptability. Users do not need to make a lot of configurations.

Leading algorithms: The algorithms have been comprehensively upgraded, with multiple built-in order dispatching, path planning, and traffic control algorithms. The self-developed MAPF algorithms improve the intelligence of path planning, basically achieving no deadlock. The self-developed comprehensive advanced collision detection algorithm and Safe Swap traffic control algorithm have better detection and planning for empty and full loads, oversized, oversized goods, narrow roads, rotational collisions, multi-model collisions, close-range queuing, and opposite wrong vehicles. It has a resource application mechanism between robots and systems, and systems and third-party systems, better handling recognition and third-party scheduling integration issues.

High scalability: Supports Python, JavaScript customization of system functions; supports script extension of support for third-party equipment; supports custom HTTP, Web Socket interfaces for easy connection with ERP, dashboards, and other third-party systems.

Easy to use: Plug and play, with fewer configurations; clear interface interaction, compatible with mobile phones and tablets, supports mouse and touch operations, supports map and configuration modification on mobile phones, one-key import and export, and more convenient debugging and analysis.

3. 3D vision, robot visual map Meta-map Pro

Meta-map Pro has built a 1:1 3D scene model based on the actual exhibition site, and real-time captures the robot's position, action, task, and other data, dynamically restoring the automation process of the real scene in real time.

With the side data chart, it comprehensively displays robot status, task, operation, and maintenance-related data. It supports custom configuration of personalized data dashboards, and the scene area also supports manual drawing and model dragging. On-site audiences can personally experience exploring the 3D robot world through a game controller.

Deepening Global Construction: Comprehensive Certification for Continuous Support

On the morning of October 29th, at the exhibition site, TÜV Rheinland of Germany officially granted the EU CE-MD, CE-RED, and North American TUVus, FCC safety and regulatory compliance certifications to SEER Robotics' multiple product series.

Left: Mr. Dan Ming, General Manager of Industrial Machinery, TÜV Rheinland Greater China

Right: Mr. Guo Fangxin, Head of Overseas Business, SEER Robotics

As an internationally authoritative testing and certification body, TÜV Rheinland has systematically evaluated SEER Robotics' new products based on multiple international standards. The passage of this dual certification marks that SEER Robotics' new products fully meet the strict entry requirements of the European and American markets in terms of safety, reliability, and compliance. It has laid a solid foundation for expanding the global market and further empowered the company to provide high-performance, full-scenario robot solutions for international customers.

At present, SEER Robotics' products and services have covered more than 65 countries and regions worldwide. By establishing in-depth cooperation with local integrators, an efficient joint operation system and service network have been built to provide customers with 7x24h technical support. This helps global manufacturing enterprises accelerate intelligent upgrading based on the SEER Robotics open platform.

On the afternoon of October 29th, SEER Robotics was invited to participate in a roundtable forum. Together with Mr. Greg Baer, Vice President of Sales of the MHI Association in the United States, they had an in-depth dialogue around topics such as how Chinese robot companies can efficiently expand into the North American market. They discussed the ways to break through the North American market and explored new ideas for Chinese robot companies to go global.

Register below to request tickets