DATE: 2025/12/05

SEER Robotics’ Embodied Robots Make Their Overseas Debut: Nebula Redefines a New Paradigm for Robotics Acquisition

The development trajectory of the intelligent robotics industry is undergoing a clear, phased transformation. The industry is shifting from the early stage of “software programmed, hardware scenario-bound” fixed-scenario machines toward “software universalized, hardware scenario-bound” flexible collaborative systems. With ongoing breakthroughs in embodied intelligence and other key technologies, the industry is moving toward a future where both software and hardware become universal. In this stage, general-purpose systems and specialized equipment will coexist for the long term, jointly supporting intelligent needs across diverse scenarios.

Within this trend, humanoid robots—one of the most imaginative carriers of embodied intelligence—are advancing rapidly. They have moved beyond laboratory-bound fixtures to become mobile systems capable of executing multi-task instructions. However, achieving large-scale commercial deployment still faces core challenges: how to evolve from passive execution to autonomous operation, by integrating scenario-customized hardware with universal software capabilities.

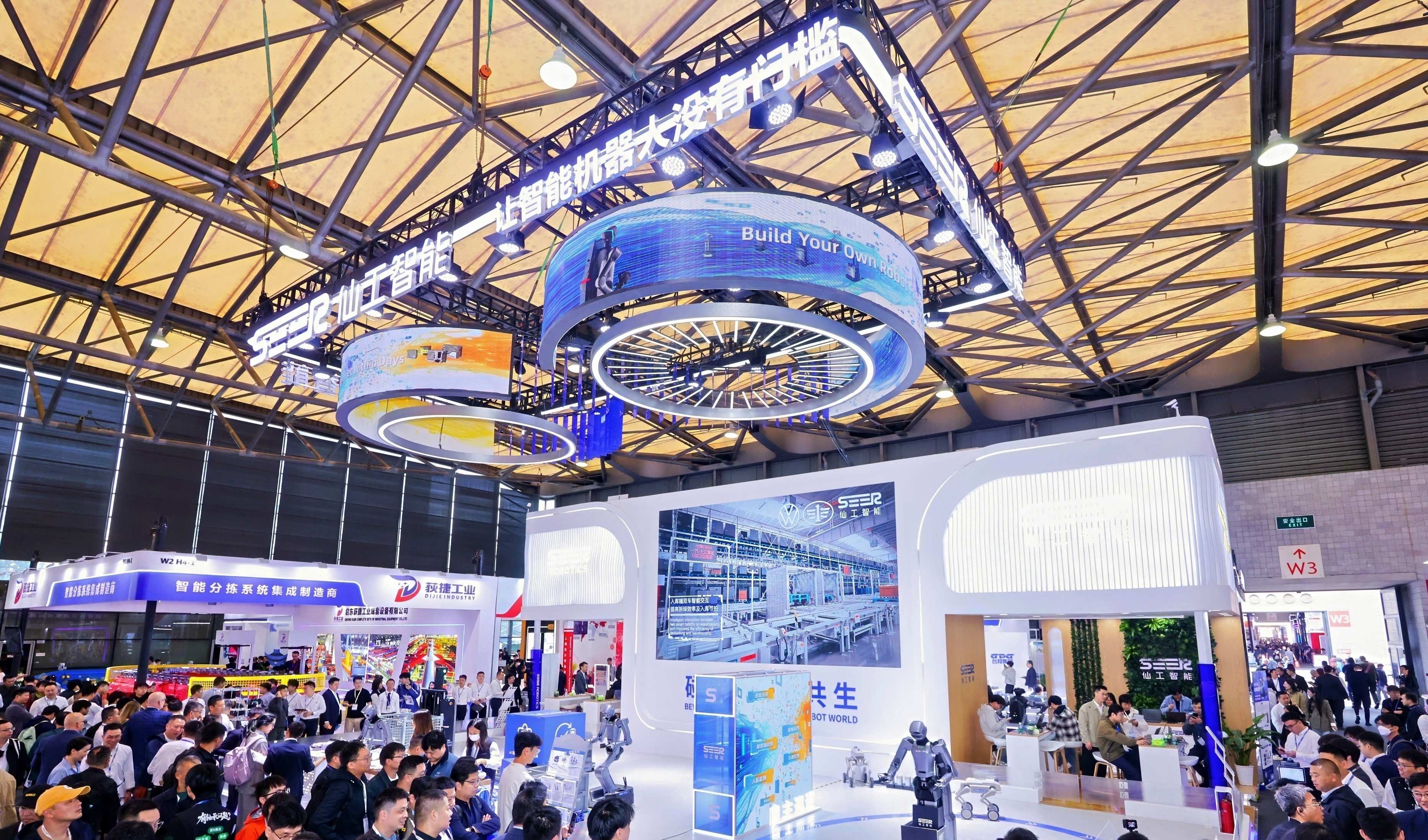

At this critical transition point, SEER Robotics offered a clearer answer with its overseas debut of embodied intelligence products. This week, its wheeled humanoid robots and quadruped robot dogs made a collective appearance on the global stage. Their debut not only showcases the industry phase of “software universalization, hardware scenario-specificity,” but also represents SEER Robotics’ systematic response to the global market—powered by its strong technological foundation and open platform ecosystem.

Behind the Debut: A Shift from “Project Customization” to “Product Configuration”

The international recognition earned by SEER Robotics’ embodied intelligence products reflects both their adaptability in complex environments and their advanced interactive capabilities. This success stems from SEER Robotics’ powerful robot intelligence system—yet equally essential is Nebula, the platform that enables rapid deployment and scalable application of embodied intelligence robots.

No two factories in the world are identical, and traditional robots often rely on high-threshold, long-cycle “project-based customization,” which becomes a major obstacle to digital transformation.

Nebula, a one-stop robotics platform integrating robot selection, intelligent simulation, and an auxiliary components marketplace, aims to transform robotic deployment into a flexible, standardized “product configuration” experience.

Users no longer need lengthy development cycles starting from scratch. Instead, they can quickly assemble robot solutions—much like building with LEGO—using Nebula’s extensive library of standardized modules and visual configuration tools, enabling truly barrier-free access to robotics.

Platform Empowerment: Unlocking Deep Scenario Value

Frontier Technology: Embodied Intelligence Series

The wheeled humanoid robot showcased overseas is equipped with SEER Robotics’ control system. It integrates the high mobility of a wheeled chassis with the high-degree-of-freedom manipulation of a humanoid upper body, forming a closed-loop intelligent system that unifies “operation + mobility.” This enables both wide-range, safe movement and precise manipulation tasks.

The full robot system includes a comprehensive multimodal perception suite, supporting multi-layer semantic maps and VLA models at the edge. It demonstrates strong generalization across scenarios such as tabletop pick-and-place, loading/unloading, and sorting.

The quadruped robot dog, also equipped with SEER Robotics’ intelligent control system, supports upgraded 3D autonomous navigation. Its reinforcement-learning-based active disturbance-rejection algorithms and high-torque joint design allow it to resist external interference, maintain stable posture, and achieve autonomous multi-terrain locomotion with agile running and jumping.

Rooted in Industrial Foundations: Scenario-Specialized Solutions

Nebula currently houses more than 1,000 robot models—each derived from SEER Robotics’ deep understanding of industrial pain points and representing a validated optimal solution for classic application scenarios. More importantly, all models are built on SEER Robotics’ unified control system, enabling cross-model and cross-scenario collaboration and centralized scheduling for true plant-wide integration.

Below are the solutions demonstrated overseas for typical factory scenarios:

Scenario 1: Closed Pallet Intensive Storage Handling

Pain points:

Closed pallets feature sealed bottoms, preventing traditional forklifts from inserting forks. In dense storage environments, spatial constraints further reduce utilization and operational efficiency.

Solution:

The E-series closed-pallet forklift, designed specifically for this challenge, uses ultra-low forks and a compact body structure to lift goods directly from beneath closed pallets. Combined with intelligent navigation and AI perception, it enables precise and efficient handling within extremely limited space.

Scenario 2: Ultra-Narrow Medical Clean-Room Logistics

Pain points:

Hospital corridors and lab passages are narrow, and manual transport of medical waste or containers poses safety and efficiency risks.

Solution:

A single-arm intelligent forklift with an ultra-narrow body can maneuver and turn flexibly within confined spaces. Its AI-based vision system ensures precise container engagement and automated waste transfer, eliminating human contact risks.

Scenario 3: High-Level Storage and Multi-Layer Palletizing/Depalletizing

Pain points:

Traditional methods for high-bay pallet operations suffer from low efficiency, poor accuracy, and significant safety hazards.

Solution:

A high-reach intelligent forklift provides precise multi-layer storage and retrieval, supported by 360° safety protection to deliver fast, accurate, and safe high-bay automation.

Scenario 4: Automated Material Flow at Production Lines

Pain points:

In discrete manufacturing and small-batch production, material transport requires high-frequency, dynamically changing paths that cannot be met by fixed conveyors or manual handling.

Solution:

The rotary-lifting transport robot features a unique rotating lift and supports on-the-spot turning with autonomous path planning. It delivers materials on demand in compact, dynamic environments, adapting flexibly to production line adjustments and order variations.

With this overseas debut, SEER Robotics solidifies its innovative presence on the global stage. More importantly, Nebula, through its standardized and modular architecture, establishes a simplified and accessible pathway for customers worldwide—offering a more efficient, reliable, and user-friendly approach to robotics adoption. This is not only a faster way to acquire robots but also a critical foundation for achieving precise and intelligent transformation.

For robotics solutions, choose Nebula.

Register below to request tickets