DATE: 2025/03/12

Live from LogiMAT | SEER Robotics Makes a Triumphant Return to Germany’s LogiMAT 2025, Earning European Recognition for High-Level Intelligence

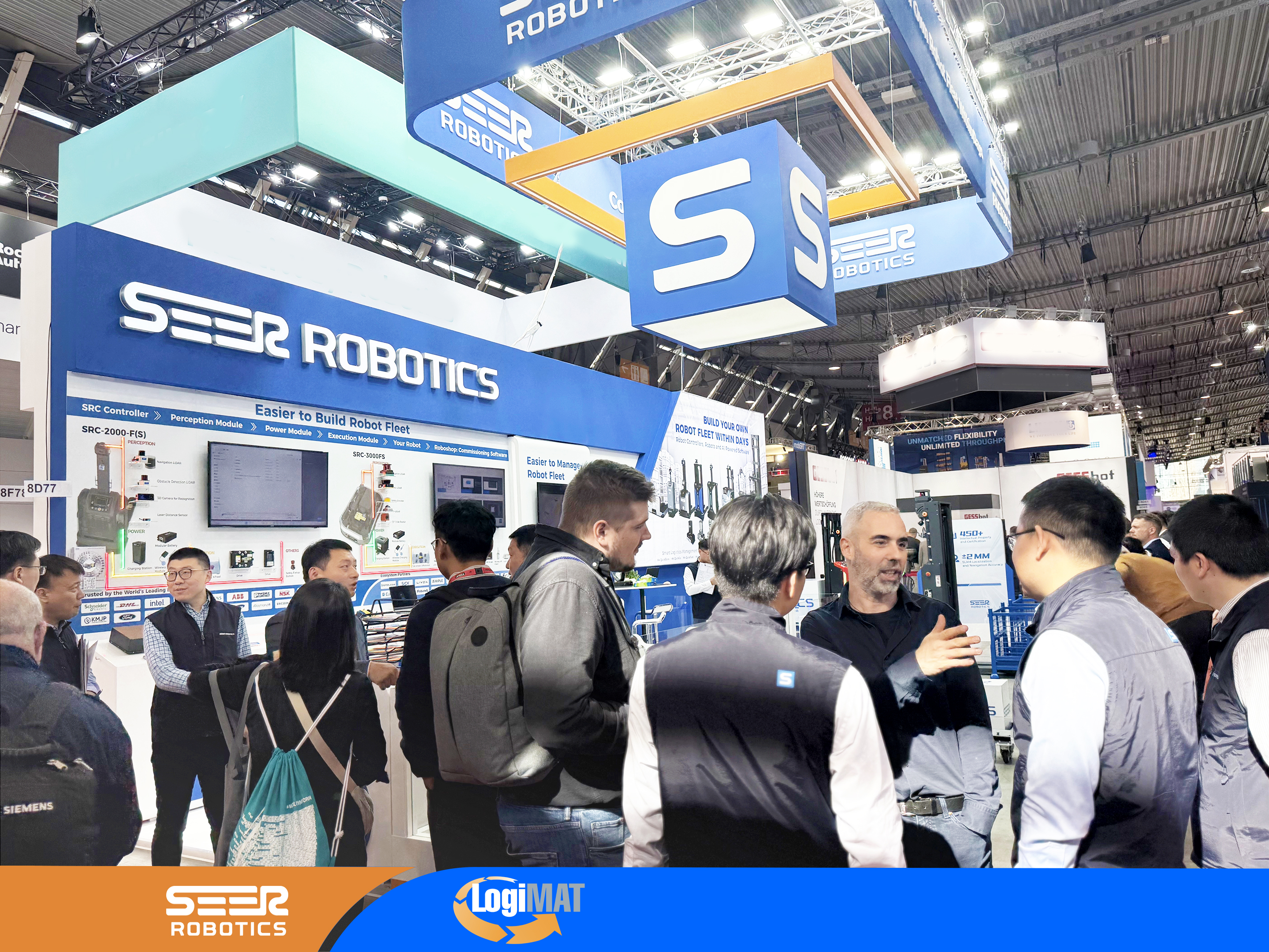

On March 11, 2025, LogiMAT Stuttgart officially opened at the Stuttgart Trade Fair Centre in Germany.

As a pioneer in the robotics industry, SEER Robotics made its third appearance at LogiMAT. Since its debut at the event, the company has garnered widespread attention from international customers with its diverse products and technological advantages, offering comprehensive solutions. This year’s exhibition, themed "Build Your Own Robot Fleet Within Days," focused on addressing user pain points and real-world application scenarios, attracting numerous visitors to engage and explore.

At the open-concept booth of SEER Robotics, a diverse range of intelligent forklifts was on display, including stackers, ground transport models, and single-fork arm types. Additionally, the company showcased its all-in-one robotic manufacturing solutions, fleet management systems, and visualization products. Through the deep integration of software and hardware innovations, SEER Robotics presented global customers with a highly efficient, full-process, and all-scenario solution centered around robotics for manufacturing, selection, and deployment.

More Versatility: CE-Certified Product Line

1. Efficient Stacking for Maximized Space Utilization

The stacker-type intelligent forklift SFL-CDD14-CE, a preferred choice among European customers, made a return to LogiMAT this year with its outstanding performance and flexibility. On-site, the forklift demonstrated its multi-layer cage stacking capability, significantly enhancing vertical space utilization. Equipped with high-precision positioning and AI-driven algorithms, it ensures operational safety and stability while improving overall efficiency.

The SFL-CDD14-CE is equipped with advanced 3D LiDAR and vision sensors, enabling high-precision recognition of cage dimensions, shapes, and positions. Utilizing SEER Robotics' proprietary AI adaptive algorithm, the forklift can dynamically calculate its relative position and posture in real time, automatically adjusting for deviations to ensure precise fork placement. During the stacking process, it continuously monitors the position and angle of the cages, autonomously adjusting its posture without the need for human intervention, ensuring the stability and safety of each stacked layer.

Powered by AI-driven algorithms, the SFL-CDD14-CE is not limited to handling cages—it also supports the recognition and transportation of various non-standard pallets, racks, and other load carriers. This versatility allows it to meet diverse operational requirements across different scenarios, offering broad adaptability in logistics and warehousing applications.

To offer customers a broader range of choices, SEER Robotics made its global debut of the higher-load SFL-CDD15-CE at LogiMAT. This new model combines high load capacity with exceptional flexibility. Built on a Linde-based chassis, it guarantees top-tier performance and reliability. Additionally, it supports various customization options, including adjustable fork height and width, making it adaptable to more complex operational scenarios and providing customers with a more versatile and efficient material handling solution.

2. Fast Ground Transport with Extended Endurance

The SFL-CBD15-CE, a ground-transport forklift, is another top choice for European customers. Leveraging SEER Robotics' proprietary high-precision LiDAR SLAM navigation technology, it enables trackless autonomous path planning and dynamic adjustments, seamlessly navigating complex environments without requiring any modifications to existing facilities.

At LogiMAT, the SFL-CBD15-CE demonstrated its high-precision positioning and intelligent path-planning capabilities, effortlessly handling curved routes and narrow aisles. With a maximum speed of 2m/s—twice as fast as traditional transport vehicles—it delivers a significant boost in operational efficiency.

The SFL-CBD15-CE is equipped with a dual-battery system, providing extended runtime with a maximum operating endurance of up to 8 hours. It also supports fast charging, requiring only 1 hour to charge from 10% to 80%, ensuring 24/7 uninterrupted operation to meet the demands of fully autonomous factory environments.

3. Lightweight Transport – The Compact Choice

For small-scale handling, SEER Robotics introduced the SOF-300EU, a single-fork-arm forklift designed for narrow aisle navigation and lightweight transport in high-density storage environments. With a width only one-third that of conventional forklifts, its streamlined and compact design makes it an optimal choice for operations requiring agility and space efficiency.

Built on a modular design, the SOF-300EU offers extensive customization options, including adjustable forks, load capacity, and vehicle height, providing customers with greater flexibility to meet diverse operational needs.

With a repeat positioning accuracy of ±2mm—among the best in the industry, the SOF-300EU delivers exceptional precision and consistency, outperforming similar forklifts on the market and ensuring reliable high-precision handling.

Furthermore, AI deep learning enhances the SOF-300EU’s ability to adapt to complex environments, enabling it to identify and handle load carriers of various colors, sizes, and conditions—including damaged or film-wrapped items. Even when dealing with carriers with unsecured swivel casters, the SOF-300EU ensures stable and efficient material handling.

More Power – One-Stop Robotic Manufacturing Solutions

Beyond forklifts, SEER Robotics offers a comprehensive, one-stop robotic manufacturing solution based on SRC controllers, enabling the development of top-lift robots, tote-handling robots, composite robots, humanoid robots, and more. Designed to meet the diverse needs of different application scenarios, this solution ensures that building robots is effortless and accessible.

The one-stop robotic manufacturing solution provides complete hardware support, including:

Core control modules

Perception modules

Execution modules

Energy modules

At the heart of the solution is SEER Robotics' SRC series controllers, allowing customers to select the appropriate controller based on their robot’s performance requirements. Options include:

SRC-880 (Entry-level)

SRC-2000 Series (General-purpose)

SRC-3000FS Series (Safety-focused)

This modular and scalable approach ensures seamless customization, enabling businesses to rapidly build and deploy their own robotic solutions across various industries.

The perception, execution, and energy modules are sourced from SEER Robotics’ carefully curated partner component library, which includes components from over 90% of mainstream sensor and drive manufacturers. This library is continuously expanding to support even more suppliers. At LogiMAT, the component wall display featured products from leading brands such as SICK, KINCO, and P+F, demonstrating SEER Robotics' commitment to offering customers a diverse and extensive selection for building their own robots.

Beyond hardware, SEER Robotics also provides Roboshop, a one-stop deployment tool, designed to rapidly implement and configure multiple robots. This tool enables customers to quickly set up and fine-tune their robotic fleets, significantly reducing deployment time and implementation costs, making automation more accessible and efficient.

At the SEER Robotics booth, the SBA-400EU, a safety-focused robotic chassis built on the SRC-3000FS controller, was showcased. This model features a transparent shell design, allowing visitors to clearly see its internal structure. Additionally, it was demonstrated in synchronized operation via Roboshop, simulating equipment debugging to provide customers with an intuitive understanding of both hardware layout and software deployment.

Beyond the hardware, SEER Robotics also offers a robot manufacturing selection guide, a wealth of reusable manufacturing case studies, as well as training programs and after-sales support, enabling customers to effortlessly build robots without barriers.

More User-Friendly – Making Robotics Accessible to All

The efficiency of robots in real-world applications is the key to unlocking their full value. SEER Robotics is committed to eliminating barriers to robot adoption by providing powerful yet easy-to-use digital software solutions that maximize automation potential.

At the heart of this approach is the RDS Unified Resource Scheduling System, designed to centrally manage all robots and automated logistics equipment within a factory. By enabling coordinated scheduling and seamless operation across the entire facility, RDS ensures smooth, efficient, and highly automated logistics workflows.

The RDS system is also built with user convenience in mind, offering multi-terminal seamless switching. Customers can flexibly operate the system across smartphones, tablets, and computers, with strong cross-platform compatibility ensuring a truly intuitive and uninterrupted user experience. This significantly enhances ease of use, making robotic deployment and management more accessible than ever.

To meet complex business requirements, the RDS system utilizes a low-code engine, enabling customers to customize component modules and rapidly build business workflows. Additionally, the system supports script customization and secondary development, effectively lowering the development barrier while meeting the individualized needs of customers.

SEER Robotics leverages its powerful digital technologies to provide highly immersive and real-time visual solutions for industrial environments. The goal is to enable efficient management and precise monitoring of robots and intelligent factory equipment through full-level monitoring, complete feature integration, and lifecycle visualization. This allows factory managers to real-time and intuitively grasp production dynamics, optimize resource allocation, and boost production efficiency.

This includes three mature products: the 2D Robot Visualization Map Meta-Map, the 3D Robot Visualization Map Meta-Map Pro, and the 3D Digital Twin Meta-World.

Exciting Highlights – Live Events Ongoing

During the exhibition, SEER Robotics hosted a partner certification ceremony, which became one of the major highlights at the booth. On the first day, Slovak integrator iGrow Network and Hungarian robotics manufacturer Hesse Robot participated in the certification ceremony, which is still ongoing. This certification not only reflects the strong trust and recognition from multiple partners in SEER Robotics’ capabilities in the robotics field but also marks a new milestone in SEER Robotics' collaboration with European integrators and robotics manufacturers.

The SEER Robotics booth also featured a wide range of online and offline interactive activities, including YouTube live broadcasts, European media dialogues, software interactions, and debugging experiences. These activities provided visitors with the opportunity for close engagement and a deeper understanding of SEER Robotics, significantly enhancing the audience’s sense of participation and overall experience.

Over the years, SEER Robotics has remained deeply committed to the robotics industry, focusing on advanced control systems and digital software as core technologies. With deep insights into various industry segments, SEER Robotics continues to drive product innovation, offering full-process, all-scenario robotic solutions.

From automotive, 3C, and new energy to textiles, lithium batteries, and other manufacturing sectors, SEER Robotics' high-quality products and services have been implemented in over 65 countries and regions worldwide, earning widespread recognition and praise. These solutions are helping numerous industries achieve intelligent upgrades.

The excitement of LogiMAT Stuttgart 2025 continues—Hall 8, Stand 8D77. SEER Robotics looks forward to your visit!

Register below to request tickets