DATE: 2025/03/18

Straight from PROMAT | Gathering Innovation, SEER Robotics Shines in the Americas to Expand the Robotics Ecosystem

On March 17, the PROMAT 2025 International Material Handling and Logistics Exhibition officially opened at McCormick Place in Chicago, USA. As a flagship event in the global logistics and supply chain industry, this year’s PROMAT is themed “Innovation and Sustainability,” focusing on robotics, automation solutions, and green supply chains.

SEER Robotics, under the theme “Build Your Own Robot Fleet Within Days,” made a grand appearance at booth E12013 in the Lakeside Hall, showcasing new robots and core products. With its one-stop solutions, SEER Robotics brings a tailor-made intelligent robotics innovation experience to the North American market.

As an all-in-one robotics platform, SEER Robotics always takes customer scenario needs as the source of innovation. Relying on its AGI-powered core technology, SEER Robotics has built a seamless closed-loop system for the development–acquisition–application of intelligent robots. The company continues to push the boundaries of robotic performance, leveraging an open and collaborative ecosystem to connect the entire robot lifecycle service chain. By strengthening its platform advantages, SEER Robotics empowers businesses to Build Your Own Robot Fleet Within Days, accelerating the global wave of industrial intelligence to new heights.

New Product Launch in the Americas: Scenario-Focused Intelligent Tools

At this exhibition, SEER Robotics is unveiling two brand-new products for the American market. With patented designs and localized adaptability, these products directly address the core pain points of North American robotics application scenarios.

1. SPT-1000 Ground-Based Autonomous Forklift

The SPT-1000 breaks away from the traditional forklift structure with an innovative fork-pallet design. It supports seamless docking with mainstream closed pallets in the Americas and flexibly handles various pallet transport tasks. Equipped with built-in AI recognition technology, it offers significantly enhanced adaptability, greatly improving handling efficiency and operational stability.

The SPT-1000 features a compact body width of only 1.2 meters and can smoothly operate in ultra-narrow aisles as tight as 1.3 meters. It has a load capacity of 1,000 kg, with customization available up to 1,500 kg. Its compact design allows it to easily navigate narrow and densely packed areas, making it particularly well-suited for pallet handling in space-constrained environments.

2. SSR-1400 Slim Reach Autonomous Forklift

The SSR-1400 is equipped with adjustable fork spacing, allowing fork width to be flexibly adapted to specific handling requirements. Combined with built-in AI recognition, it automatically matches the optimal fork distance, breaking the traditional forklift’s rigid dependence on fixed pallet specifications. In addition, fork movements are controlled by highly flexible scripting, supporting a variety of fork action combinations. This greatly enhances adaptability across different application scenarios, enabling a single machine to handle multiple pallet sizes and diverse environments with ease.

The design of the SSR-1400 is nothing short of exceptional. Compared to counterbalance forklifts, it offers a smaller right-angle stacking width and more compact dimensions for the same load capacity, enabling more flexible and efficient operation in confined spaces and significantly improving space utilization. Compared to standard slim stacker forklifts, the SSR-1400 not only perfectly accommodates closed pallets with the same load capacity but also provides enhanced structural stability. This ensures greater safety and efficiency throughout operations, delivering outstanding overall performance advantages.

The SSR-1400 supports stacking, reach, and transport operations up to a height of 3 meters, with a maximum load capacity of 1,400 kg. It offers an impressive battery life of up to 10 hours, meeting the heavy-load and long-endurance handling demands of industries such as warehousing and logistics, automotive manufacturing, and machinery manufacturing.

Classic Product Upgrades: Full Scenario Coverage

In addition to new products, SEER Robotics is showcasing a variety of proven product portfolios, providing North American customers with one-stop robotics solutions from hardware to software.

1. Compact Size, Powerful Performance

The SJV-SW600 Rotating Lift Robot features a unique rotating lift structure. Powered by an integrated SRC controller, it synchronously controls both the robot’s steering and the rotation of lifted goods. This allows for effortless maneuvering in narrow aisles while keeping the cargo orientation unchanged, enabling highly flexible handling in space-restricted environments.

The SJV-SW600 has a maximum load capacity of 600 kg and can reach speeds of up to 1.5 m/s under full load. Equipped with dual laser sensors on both the front and rear, it ensures enhanced safety throughout operations.

The SOF-300EU Single-Arm Autonomous Forklift features a body size only one-third that of a conventional forklift, making it perfectly suited for dense storage environments and the handling of small carriers and lightweight materials.

At PROMAT, a dedicated interactive zone was set up for the single-robot dispatch solution, QuickGo. Visitors could operate the remote-control interface via tablet and experience driving the SOF-300EU autonomous forklift firsthand on site.

QuickGo has been fully upgraded to version 2.0, enhancing its core dispatching capabilities while simplifying deployment, operation, and resource requirements. Designed for out-of-the-box use, it aims to provide users with a more convenient and seamless single-robot dispatching experience.

2. One-Stop Robot Development Solution

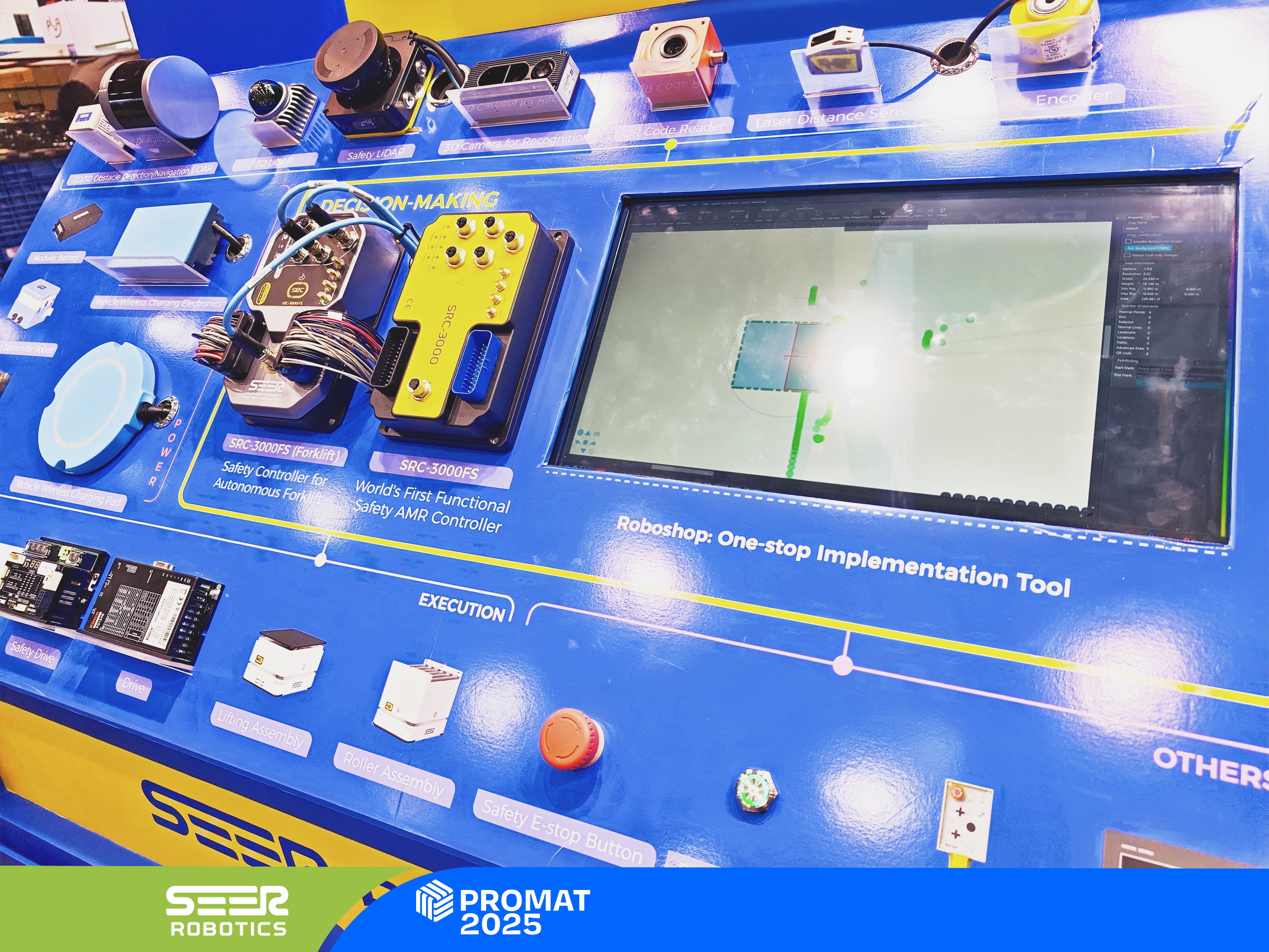

The one-stop robot development solution, centered around the SRC controller, is designed to provide robot manufacturers with the full industry chain hardware of "controller + components." Through more flexible, personalized, and intelligent robot development solutions, it aims to break down the barriers to intelligent robotics, enabling seamless and accessible robotics development.

At PROMAT, SEER Robotics showcased a robot development solution based on the safety controller SRC-3000FS. The displayed component products were sourced from SEER Robotics' carefully selected partner component library. These components included perception modules, execution modules, energy modules, and other modules, such as safety lasers, safety encoders, modular batteries, wireless charging modules, drivers, emergency stop switches, and more.

To make the deployment tools more intuitive, the display area featured a touchscreen interactive solution. When the power switch or emergency stop button is pressed, the one-stop deployment tool, Roboshop, immediately displays relevant power-on/off and error messages, allowing operators to clearly understand the robot’s operational status.

3. Unified Resource Scheduling System

The RDS Unified Resource Scheduling System supports the centralized management and scheduling of all intelligent devices in the factory, including robots, and seamlessly integrates with the client’s business systems. This creates a "factory-wide coordinated approach," enhancing operational efficiency. RDS eliminates the challenges of multiple system integrations, resolves device connection issues, and is compatible with various devices such as smartphones, tablets, and computers, offering seamless switching between platforms.

4. Industrial-Grade Visualization Solutions

To achieve efficient management and precise monitoring of robots and intelligent factory equipment, SEER Robotics has developed a series of industrial-grade immersive visualization solutions. These solutions enable multi-level monitoring, full-feature integration, and lifecycle-wide visualization.

The video above showcases the digital twin scene of the PROMAT booth built on Meta-World. Meta-World achieves a one-to-one accurate model, replicating real-world scenarios to ensure real-time synchronization of robots and data in the twin world with the physical environment. This enables users to make more informed, data-driven decisions.

PROMAT Excitement Continues

At the PROMAT exhibition, SEER Robotics’ booth fully demonstrated its technological strength. In addition, a variety of offline experience activities and sharing sessions were held to connect with the audience. At the same time, online engagement through YouTube live streaming allowed global viewers to participate in real-time, experiencing the exciting moments at the PROMAT booth.

PROMAT 2025 is in full swing! Visit SEER Robotics at booth E12013 in the Lakeside Hall – we look forward to welcoming you!

Register below to request tickets