DATE: 2025/07/16

Empowered by the Nebula System, Building Your Own Robot Fleet Within Days!

As the wave of intelligent factory logistics and warehousing sweeps across industries, companies still face three major challenges when introducing smart robotics solutions:

1. Lengthy selection, customization, and delivery cycles: How to quickly obtain robots perfectly suited to specific business scenarios?

2. Complex peripheral expansions: How to flexibly integrate accessories like LiDARs, sensors, and drivers?

3. Difficult functional customization: How to meet diverse and unique robotic functional requirements?

To address these pain points, SEER Robotics has independently developed the Nebula System, revolutionizing the way robots are acquired with a one-stop robot selection platform, making robotics accessible to all.

The Nebula System offers a curated selection of over 1,000 robots equipped with SRC series controllers, covering various types such as wheeled humanoid robots, multi-legged robotic dogs, lifting robots, smart forklifts, tote-moving robots, cleaning robots, and all-terrain robots.

With a simple and intuitive interface, the Nebula System enables customers to achieve "what you see is what you get"—quickly selecting and configuring robots tailored to their needs. It also supports end-to-end delivery tracking, allowing customers to monitor progress at every stage in real-time and accelerate deployment.

In the first half of 2025, we launched a full range of robot products co-developed with partners on the Nebula System. From high-performance smart forklifts to agile lifting robots, from modular customizable robot chassis to specialized all-terrain robots, these offerings cover mainstream robot types. Additionally, they provide diverse load capacity options, appearance customization, product certifications, and functional add-ons, solving customers' three key pain points—rapid acquisition, flexible expansion, and functional customization.

Take the ground-handling smart forklift SFL-CBD15-ZL as an example. Through the Nebula System, users can freely select from 300+ plug-and-play accessories by SEER Robotics, optimizing the total cost of the machine to the fullest. It also supports various optional configurations such as laser navigation, pallet recognition, 3D obstacle avoidance, 3D navigation, and gimbal monitoring, along with customization options for fork width, color, and logos. The entire process, from selection to customization to delivery, is transparent and visible, enabling one-stop fulfillment of complex requirements.

Below are more smart robots customized via the Nebula System—take a sneak peek!

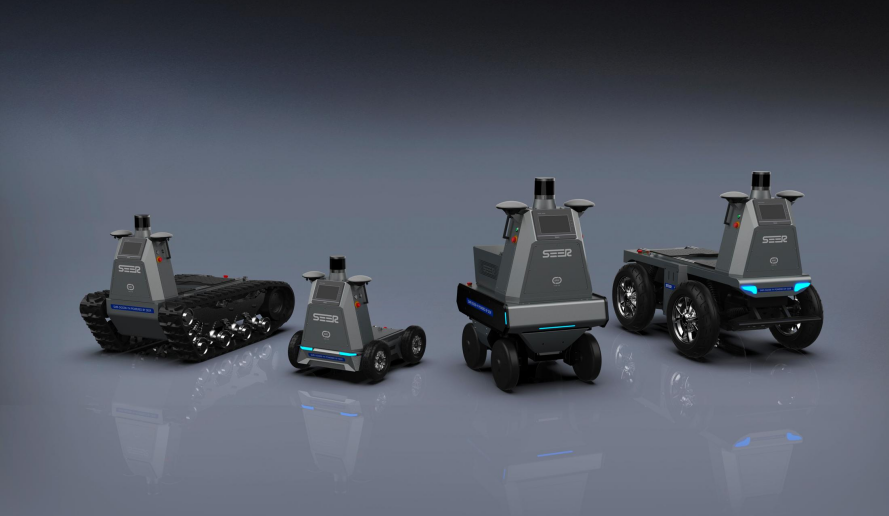

Robot Chassis

Universal Intelligence, Unlimited Expansion

1. Self-developed vehicle steady-state system for smoother operation of upper-mounted equipment.

2. Industry-first omnidirectional standard chassis, with leading positioning, navigation, and superior motion control performance.

3. Modular structure and integrated wiring design for quick change-out, enhanced convenience, and safety.

4. Ultra-thin body design with mainstream expansion interfaces, compatible with various upper-mounted mechanisms such as lifting, roller, and towing.

Autonomous Forklift

AI-empowered, High-performance Material Handling Assistant

1. Wide-range load capacity, meeting the full-scene needs from light-duty transfer to heavy-duty storage.

2. AI deep learning for adaptive identification and fork-lifting of carriers, ensuring stable pick-up and placement.

3. Modular design enhances product reliability and stability, and reduces maintenance costs.

4. Maximum travel speed of up to 2 m/s, combined with intelligent path planning for more efficient operations.

Lifting Robot

Elegant and Agile, Precise Production Line Flow

1. ± 5 mm repeat positioning accuracy, precisely meeting the dynamic production line flow requirements.

2. Lightweight and compact body, with lower environmental requirements, broader coverage of scenarios, and fewer site restrictions.

3. Modular lifting mechanism design, balancing stability and maintenance convenience.

Bin-Handling Robot

Preferred for Intelligent Warehousing

1. Integrated control by SRC controller for all-in-one control of movement and pick-up/put-down of goods.

2. Enhanced by M4 Smart Logistics Management System for real-time dynamic optimization of storage locations and intelligent order-picking.

3. Suitable for narrow aisles, higher passability, and overall improved space utilization.

All-Terrain Robot

All-purpose for Indoor and Outdoor Use

1. All-weather, multi-scenario application for both indoor and outdoor use, breaking environmental limitations.

2. Unafraid of climbing slopes, overcoming obstacles, and crossing curbs, ensuring smooth travel on complex terrains.

3. ± 2 cm precise positioning, with multiple sensors providing 360-degree safety assurance.

/1.png?x-oss-process=image/format,webp)

/1.png?x-oss-process=image/format,webp)